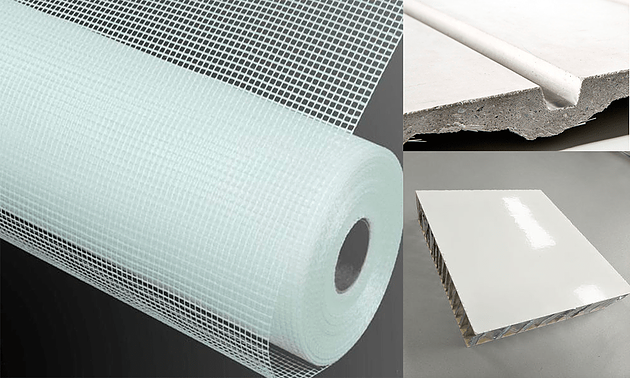

GRP Lining

STORAGE STABILITY:

POLYPOL – 1003 Unsaturated Polyester resin is stable for three months from the date of production when stored in the original containers away from sunlight &consistently at not more than 77ºF/25º C.

CURE CONDITIONS Curing of Polypol-1003 can be initiated with 1.5% of MEKP (55%) 100 ppm HQ per 100 gm of resin. Casting is allowed to cure for 24 hours at room temperature, then post-cured at 110º C for 2 hours. And again cure for one hour at 100º c. Curing should not be carried out below 15ºC and the resin must be allowed to attain ambient temperature (above 15ºC) before being formulated for use. Not to use any amines in production and post curing is essential for all types of mouldings.

Specializations

NAMING:

Example: Fiber1 ECM1 – 450E/127

Fiber1 : Trademark of Glass Fiber Technology Co. Ltd (GFT)

ECM1 : GFT Code

450 : Density (g/m²) E : Emulsion Bonded

127 : Mat Width in cm.

KEY FEATURES

- Fast & Easy Impregnation

- Fast-wet-Through and de-airing

- Excellent Conformability

- Good Mechanical Properties

- Low Resin Consumption

- Silane Based Sizing on Strands

PRODUCTS AVAILABLE The main advantage of Fiber1 ECM1 chopped strand mat is the availability of an extensive range of widths and weights (widths from 25 to 260 cm, nominal weights from 150 to 900 g/m²). Most combinations of weights and widths can be supplied. Subject in some cases to minimum order quantities, extended lead times and complementary widths.

PACKING

Each roll is put into individual carton then palletized. For bulk packing for each pallet we put 16 rolls.

STORAGE

It is recommended that fiberglass I store vertically in a cool and dry environment, with recommended storage temperatures ranging between 10 ~ 30º C and its relative humidity between 50 ~ 75%, to avoid problems with humidity or static electricity, the glass product should be conditioned in the working area prior to use. This fiberglass should remain in the packaging prior to its use.

United Arab Emirates

B1 Block, Falcon towers, Ajman U.A.E.